Rotary drums are specially suitable to dry solid products such as raw materials coming from quarries (silca sand, limestone, clays, kaolin, etc.)

Several models are available, every drier is designed according to the specific material to be processed, requested throughput, moisture to be evaporated, available fuel.

Besides the rotary driers, Cimma supplies a wide range of drying-grinding systems.

Cimma’s engineering staff is ready for studying and solving client’s requirement for research and operation activity.

Rotary driers

Useful used for drying of minerals, sands, clays, calcium carbonate, metal shevings, marble powder, fertilizers.

• Single tube counter flow drier

• Counter flow drier

• Double cylinder drier

Production: up to 50 tons/hour

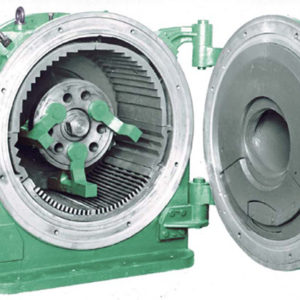

Pendular ring roller mill type “PD.1504 – PD.1200”

Ring – Roller Mill with dynamic air classifier for grinding by compression friable materials (clays, minerals, caolin, chemical products, bentonite, dolomite, coal, limestone, baryte)

Feed size: 0÷20 mm

Fineness range: 40÷300 micron

Capacity: 5-20 tons/hour

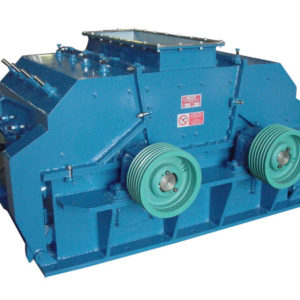

Double rotor hammer mill type “ROTODUE 4M”

Designed for production of powders / fine sands with high content of fines from materials of medium hardness and abrasiveness (calcium carbonate, dolomite, carbon coke, pet coke, lime, plaster, clays, waste brick ). Specially suited for drying and grinding in one operation

Feed size: 0-80 mm

Fineness range: 0÷3 mm

Capacity: 20-50 tons/hour

Double rotor hammer mill type “ROTODUE 4/C” with dynamic classifier

Grinding of friable, medium hardness and abrasiveness materials as carbon coke, petroleum coke, calcium carbonate, dolomite, calcium oxide, magnesium oxide, gypsum, clays

Feed size: 0-20 mm

Fineness range: 0÷100 micron

Capacity: up to 10 tons/hour

Pulverizer type “SV MICRO” with dynamic air classifier

Pulverizer suited for fine and very fine grinding of medium hardness materials as: minerals, chemicals, vegetal products, pet coke, activated carbon The dynamic air classifier built inside the machine allow to control the fineness of the product.

Feed size: 0 – 10 mm

Fineness range: 0 ÷ 40 micron

Capacity: 300 – 3000 kg/hour

Pulverizing mill type “SF”

Pulverizing cells mill type SF Suited for pulverizing and micronizing of non abrasive materials as: rubber, plastic products, chemicals, calcium carbonate, sawdust, cereals, metal oxide, lime, plaster.

Feed size: 0 – 10 mm

Fineness range: 20 ÷ 100 micron

Capacity: 300 – 5000 kg/hour

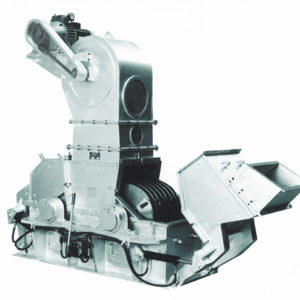

Universal impact mills type “P – D – PC”

Very versatile Mills for grinding / pulverizing by impact and friction action, many different kinds of dry and friable materials . Particularly suitable for simultaneous drying and grinding (limestone, lime, dolomite, waste brick, granite, plaster, glass, refractory, clay, minerals abrasive media and coal).

Feed size: 0 – 100 mm

Fineness range: 0 ÷ 5 mm

Capacity: 0,5 – 15 t/hour