Thanks to the know-how acquired on the most modern processes of grinding raw materials, Cimma Morandotti S.P.A. proposes machines and complete industrial plants for the main application markets: mining – ceramics – bricks – chemical – food – biomasse, solid fuels and plastics;

Besides grinding, CIMMA developed processes with air classified mills, drying and grinding systems, grinding processes in inert circuit and applications according to ATEX Standards

Cimma Morandotti S.P.A. offers to clients, research and development facilities, technical support, the experience of its technical staff to meet and solve all the requirements of the project development.

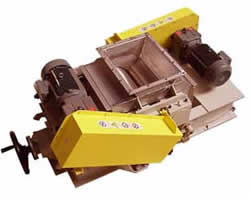

Single and double rotor lump breaker type “RIP”, “RG”, “SM”

The lump breaker model RIP /RG – SM is designed to be used as primary crusher for materials agglomerated in lumps, even moist (10-20%) – not particularly hard such as clays, bentonite, chemical products, fertilizers, casting earth.

Feed size: 0 – 400 mm

Fineness range: 10 ÷ 60 mm

Capacity: up to 100 m3/hour

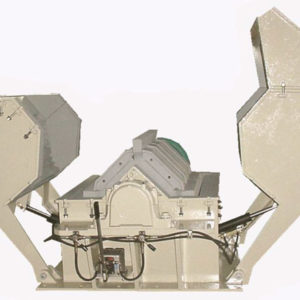

Impact crushers type “II/A-III-IV-V-V/S”

Primary/secondary crusher by impact action for materials as limestone, chamotte, clay, minerals, gypsum, lime.

Feed size: 0 – 400 mm

Fineness range: 10 ÷ 60 mm

Capacity: up to 100 t/hour

Single rotor mill type Rotouno MXP

Precrusher without screen suitable for hard and abrasive products such as gres porcellanato, waste brick, granite, limestone, dolomite, glass, refractory.

Feed size: 0-200 mm or tiles up to 700×700 mm

Fineness range: 10 ÷ 20 mm

Capacity: up to 40 t/hour

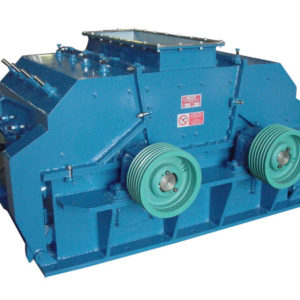

Roll crusher

Grinding materials of medium size by crushing action, with low content of fine powder into the product (coal, fertilizers, chemical products, glass, granite, bones).

Feed size 0 – 20 mm

Fineness range: the fineness adjustable up to 0,5 mm, depending by the rolls distance

Capacity: up to 15 t/hour

Universal impact mills type “P – D – PC”

Very versatile Mills for grinding / pulverizing by impact and friction action, many different kinds of dry and friable materials . Particularly suitable for simultaneous drying and grinding (limestone, lime, dolomite, waste brick, granite, plaster, glass, refractory, clay, minerals abrasive media and coal).

Feed size: 0 – 100 mm

Fineness range: 0 ÷ 5 mm

Capacity: 0,5 – 15 t/hour

Single rotor hammer mill type “ROTOUNO”

Designed for production of powders / fine sands with high content of fines from materials of medium hardness and abrasiveness (calcium carbonate, dolomite, carbon coke, pet coke, lime, plaster, clays, waste brick).

Feed size: 0 – 80 mm

Fineness range: 0 ÷ 3 mm

Capacity: 20 – 30 t/hour

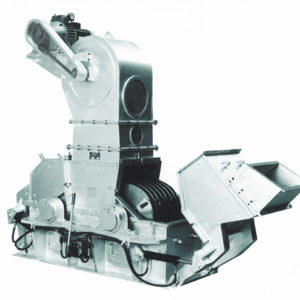

Double rotor hammer mill type “ROTODUE 4M”, suitable for grinding and drying

Designed for production of powders / fine sands with high content of fines from materials of medium hardness and abrasiveness (calcium carbonate, dolomite, carbon coke, pet coke, lime, plaster, clays, waste brick ). Specially suited for drying and grinding in one operation.

Feed size: 0 – 80 mm

Fineness range: 0 ÷ 3 mm

Capacity: 20 – 30 t/hour

Fixed hammer mill type “COMBI”

Designed for production of powders / fine sands with high content of fines from materials of medium hardness and abrasiveness (calcium carbonate, dolomite, carbon coke, pet coke, lime, plaster, clays, waste brick).

Feed size: 0 – 150 mm

Fineness range: 0 ÷ 3 mm

Capacity: 20 – 50 t/hour

Laboratory and small capacity mills for pulverizing dry materials of low/medium hardness as: spices, dry vegetables, colours for ceramic industry, plastic materials, chemical products, food. Construction materials carbon steel or stainless steel (AISI 304 – AISI 316).

Feed size: 0 – 20 mm

Fineness range: 0 ÷ 2 mm

Capacity: 30 – 1000 kg/hour

Pin mill type contrarotor “C30 – C60”

Suited for pulverizing (<100 micron) of low abrasive materials as: chemicals, calcium carbonate, food products, cereals, plastic materials. Termosensible materials as: Viton, rubber, tyre, oily food products, can be easy pulverized with Contrarotor C.30 criogenic version by a prefreezing with liquid nitrogen.

Feed size: 0 – 8 mm

Fineness range: 0 ÷ 200 micron

Capacity: 80 – 1000 kg/hour

Air swept mill model “PPS” with air classifier

Suited very fine pulverizing of medium hardness materials and abrasiveness with narrow granulometry distribution and low product overheating .Suitable for chemicals products, vegetable products (calcium and zinc, stearates powder paints, chemicals products, , plants products, cocoa, soybean, mais) The fineness range is adjusted by the air classifier built in the air swept mill.

Feed size: 0 – 10 mm

Fineness range: 0 ÷ 40 micron

Capacity: 500 – 3000 kg/hour

Double rotor hammer mill type “ROTODUE 4/C” with dynamic classifier

Grinding of friable, medium hardness and abrasiveness materials as carbon coke, petroleum coke, calcium carbonate, dolomite, calcium oxide, magnesium oxide, gypsum, clays.

Feed size: 0 – 20 mm

Fineness range: 0 ÷ 100 micron

Capacity: fino a 10 t/hour

Pulverizer type “SV MICRO” with dynamic air classifier

Pulverizer suited for fine and very fine grinding of medium hardness materials as: minerals, chemicals, vegetal products, pet coke, activated carbon The dynamic air classifier built inside the machine allow to control the fineness of the product.

Feed size: 0 – 10 mm

Fineness range: 0 ÷ 40 micron

Capacity: 300 – 3000 kg/hour

Pulverizing cells mill type SF Suited for pulverizing and micronizing of non abrasive materials as: rubber, plastic products, chemicals, calcium carbonate, sawdust, cereals, metal oxide, lime, plaster.

Feed size: 0 – 10 mm

Fineness range: 20 ÷ 100 micron

Capacity: 300 – 5000 kg/hour

Pendular ring roller mill type “PD.1504 – PD.1200”

Ring – Roller Mill with dynamic air classifier for grinding by compression friable materials (clays, minerals, caolin, chemical products, bentonite, dolomite, coal, limestone, baryte).

Feed size: 0 – 20 mm

Fineness range: 40 ÷ 300 micron

Capacity: 5 – 20 t/hour

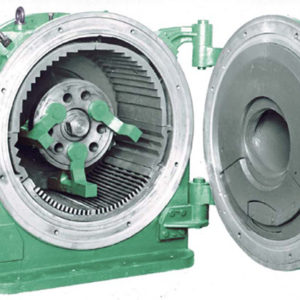

Balls Mills for dry grinding of hard and abrasive materials as silica sands, zirconium oxide, feldspar, chamotte.

Fineness range: 0 ÷ 0,5 mm

Capacity: 1 – 2 t/hour

Hammer mills type “BL ROTOSCREEN” with rotating grid

Hammer mill with welded body particularly designed for grinding vegetable products (cereals, CAROB, animal feed, non abrasive chemical product, biomasses).

Feed size: 0 – 20 mm

Fineness range: 40 ÷ 300 micron

Capacity: 5 – 20 t/hour