- Clay

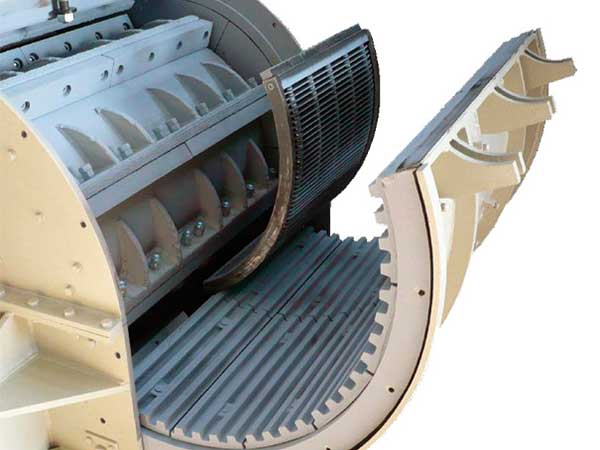

Grinding of ceramic bodies with moisture content less than 7% for bricks, roof tiles and other ceramic products, where a granulometry 0,6÷2 mm is required. Classification is obtained with vibrating screens.

- In many cases the COMBI mill can grind the oversize from the screens

- Pre-grinding of clays before fine grinding with pendular mills

- The high percentage of useful product produced directly by the COMBI mill, contributes to the best performance of the plant

- Waste of bricks, tiles, chamotte

For addition to ceramic bodies.

- Calcium carbonate, marble, dolomite

Production of sands with optimal granulometry distribution for successive classification for premixed dry mortars.

- Waste of various industrial product

Refractories, glass, ceramic products, recycling in the new production.

- Other products

Calcium oxide, hydrated lime, chemical products, petroleum coke, metal alloys.