It is well known that screen selectors become little effective when materials minus 100 micron are handled. Further the maximum output per screening surface unit of these machines is relatively low

Therefore Air selector must be installed in grinding plants when a high output of very fine material at a constant selected size range is required.

Air selector may be installed in dry-grinding plants of any kind allows to get a fine product without coarse particles.

Air selectors combines two selecting actions: air stream and centrifugal force.

A distributor plate centrifuges and shares the product to be selected while an air stream takes upwards the fine particles. Coarse particles fall along the inside walls and are discharged through a separate opening.

Fineness of the product can be selected by changing the position of the movable bars, the number of vanes of the distributor plate and/or distributor plate fan revolution speed (rpm).

Air selector increases the efficiency of grinding machines by immediately removing the fine particles as soon as they are ground to the required fineness and by feeding back only the coarse particles.

Moreover Air Selector allows to obtain a constant size product with a high global efficiency of the grinders, even when grinding parts are very worn; therefore obtaining a reduction in maintenance and attendance costs.

Inside arrangement can be changed according to the application needs. The “AERVOTEX” selector may be used even for eliminating the finest particles from sands or granulated products.

These kind of air classifier are “self ventilated” this means they don’t need a suction blower for running with strong reduction in the electric consumption.

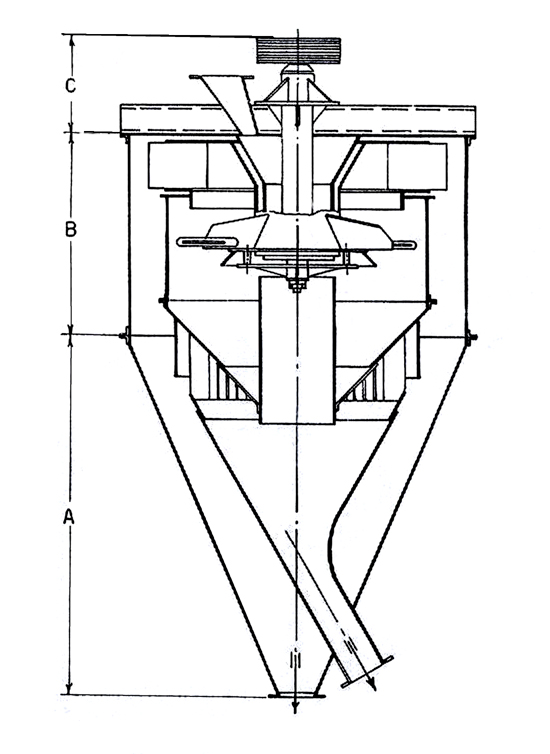

| TYPE | 185 | 230 | 280 | 350 | |

| Diameter | mm | 1850 | 2300 | 2800 | 3500 |

| Working height | A)mm B)mm C)mm |

1600 1800 850 |

1900 1660 790 |

3000 1670 840 |

3700 2250 1160 |

| Required power | kW | 4÷5,5 | 11÷15 | 15÷18,5 | 22÷30 |

| Speed | rpm | 280÷350 | 260÷320 | 240÷300 | 230÷260 |

| Capacity | t/h | 1÷1,5 | 10÷12 | 15÷25 | 35÷45 |

| Weight | Kg | 1900 | 2700 | 4000 | 9500 |

| Noise Level (1m) without noise insulation systems | db | 95 | 95 | 95 | 95 |

The data and characteristics of this table are informative and subject to change without prior notice.