The lump breaker model RIP/SM is designed to be used as primary crusher for materials agglomerated in lumps or sods such as clays, bentonite, chemical products, casting earth.

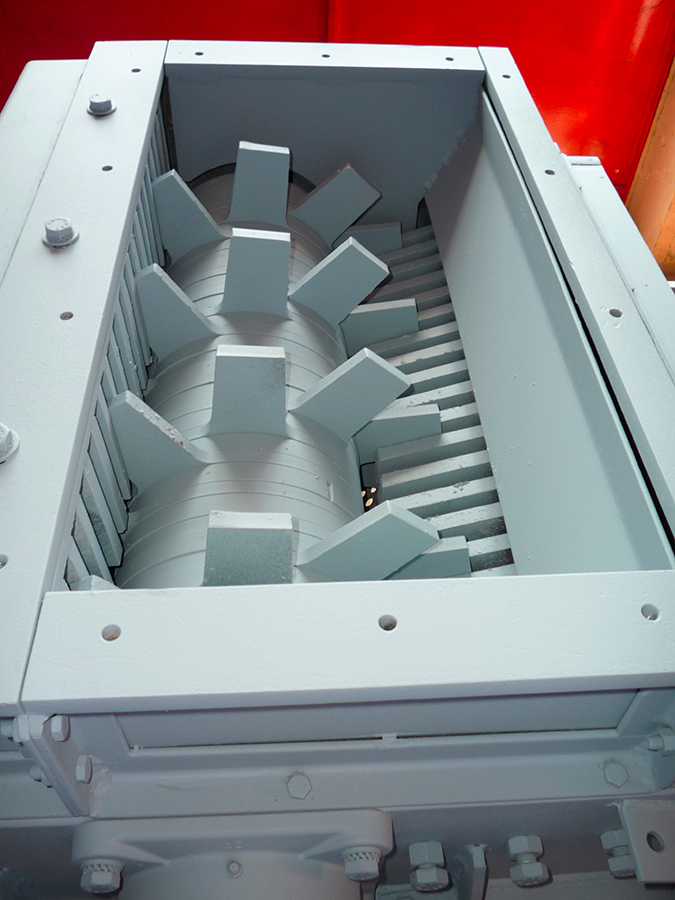

The lump breaker model RIP is mainly composed of one toothed roll that forces the material through a fixed comb, whose distance from the toothed roll is adjustable.

The specially designed disposition of teeth on the roll’s surface makes the RIP breaker able to accept lumps with large dimensions compared to the size of the machine.

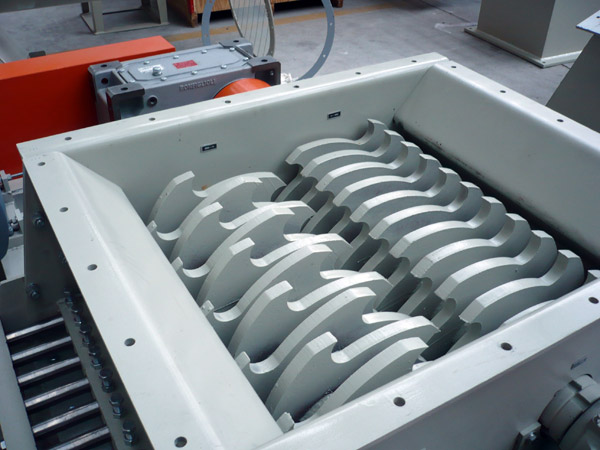

The lump breaker type SM is a double shaft lump breaker designed for high capacity (40-100 t/h)

The lump breaker type RG is single or double shaft lump breaker designed for agglomerated materials, chemicals with small capacity (range 2-6 t/h). CS or AISI stainless steel design.

Optional screen at bottom discharge can be installed in RIP and RG design.

Due to its working principle, this machine is suitable to process also materials with a high moisture content.

The drive of the lump breaker can be provided with a torque limiting device that automatically stops the machine in case of hard pieces or metals inlet.

- Lump breaker model ``RIP``

- Lump breaking discharger type ``RG``

- Double shaft lump breaker type “SM”

- Download

| TYPE | I/400 | I/600 | I/800 | III/800 | III/1000 | |

| Tip rotor diameter | mm | 370 | 370 | 370 | 600 | 600 |

| Working width | mm | 400 | 600 | 800 | 800 | 1000 |

| Required power | kW | 5,5 | 7,5 | 7,5 | 11 | 15 |

The data and characteristics of this table are informative and subject to change without prior notice.

It is a variant of the comb-type lump breaker.

It is designed to be installed directly at the discharge of silos or bins with the purpose to break those lumps that may form during the storage.

| TYPE | 300 | 400 | 600 | |

| Size of the opening | mm | 300×300 | 400×400 | 400×600 |

| Drive power | kW | 3 | 4÷5,5 | 5,5÷11 |

The data and characteristics of this table are informative and subject to change without prior notice.

For high capacity – moist and friable large size agglomerates.

| TYPE | 300 | 400 | 500 | |

| Size of the opening | mm | 800×780 | 980×800 | 1100×1100 |

| Drive power | kW | 9-11 | 15-22 | 37-45 |

| Capacity | m3/h | 20 | 40 | 100 |

The data and characteristics of this table are informative and subject to change without prior notice.