Production of granulates and sand of medium hardness rocks.

Primary crusher for clay, kaolin, scraps of refractory material, bricks, grog, glass scraps, foundry slags, salts, lime, cement and gypsum.

- BUILDING INDUSTRY

- MINING INDUSTRY

- CERAMIC INDUSTRY

- GLASS INDUSTRY

- INDUSTRIAL WASTE

- LIME, GYPSUM, CEMENT

- BRICKS AND TILES INDUSTRY

- FOUNDRY

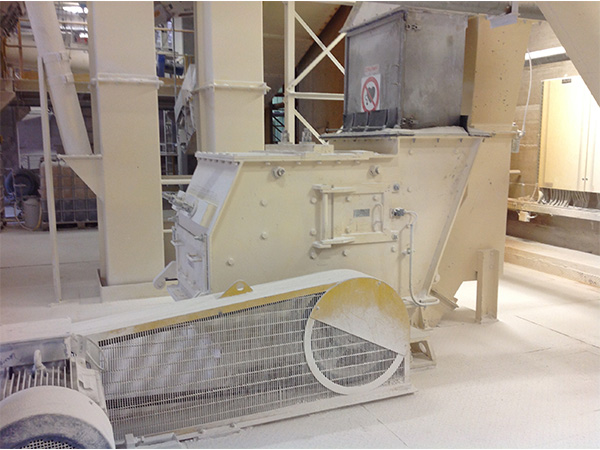

The Impact Crusher with swinging armour plates is classified among hammer mills but, in comparison with these, it offers the following advantages:

- Less wear of armour plates and hammer

- Less production of fine powders

- Possibility of processing even moist raw materials without obstruction, as there is normally no grate

- Possibility of feeding large size raw materials (200÷500 mm)

- Casing of welded steel plate, fully protected by wear resistant steel plates

- Large rotor with 4 hammers, cast in wear resistant chromium alloy or manganese steel

- Very strong and compact construction

- Very easy maintenance

- Small overall dimensions

- Possibility of adjusting the size of the product by varying the position of the armour plates and the speed

- The machine cannot be obstructed by damp materials

- The crusher can be supplied with special bar grate to obtain products with controlled granulometry, only for dry materials

| Type | Length | Width | Height | Feed opening | Capacity | Power | Speed | Weight |

| mm | mm | mm | mm | ton/h | kW | rpm | Kg | |

| IIA | 1500 | 1600 | 1530 | 500 x 770 | 12÷30 | 30÷45 | 700÷1100 | 2350 |

| III | 2300 | 1920 | 1710 | 630 x 880 | 20÷50 | 45÷75 | 600÷1000 | 5600 |

| IV | 2500 | 2500 | 1910 | 620 x 1070 | 35÷80 | 55÷90 | 600÷900 | 7200 |

| V/S | 4000 | 2550 | 2400 | 750 x 1070 | 60÷120 | 75÷110 | 500÷900 | 10000 |

The data and characteristics of this table are informative and subject to change without prior notice.