- Production of powders and fine sands of limestone and dolomite for glass factories, premixed dry mortars, agglomerated floor tiles agglomerated with cement or resins (0÷3 mm/0÷8 mm)

- Grinding of clays for production of roof tiles, bricks, extruded floor tiles

- This machine is designed for contemporary drying and grinding of wet raw materials with moisture content in the range 4-8% (depending on the raw material)

- Capacity range: 25÷60 ton/hour

- Llimestone, marble, calcium carbonate, dolomite

fine powder and sand for production of: premixed dry mortars, terrazzo tiles, animal feed, glass industry

- Gypsum

pre-grinding before calcining

- Plaster

refining for production of: plaster of Paris, plaster for ceramic moulds, special plasters

- Clay

dry grinding for: bricks, roof tiles, dressed floor tiles, abrasives, refractories, ceramic products for recycling in new production

- Waste of bricks

red earth for tennis court, chamotte for ceramic bodies

- Kaolin

scraping of pellets of washed kaolin

- Waste of industrial products, such as:

calcium oxide, hydrated lime, chemical products, horn and nails, petroleum coke, coal, metal alloys

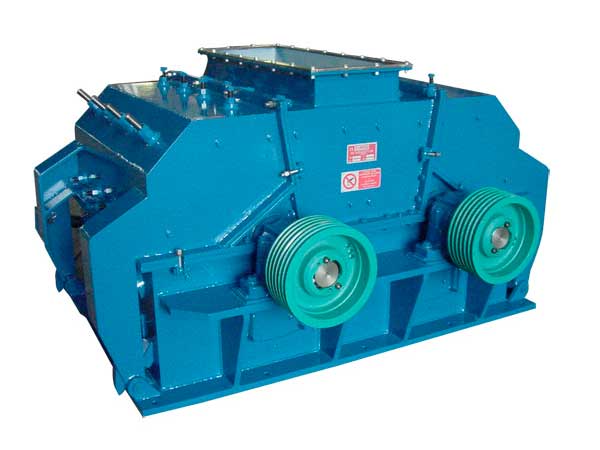

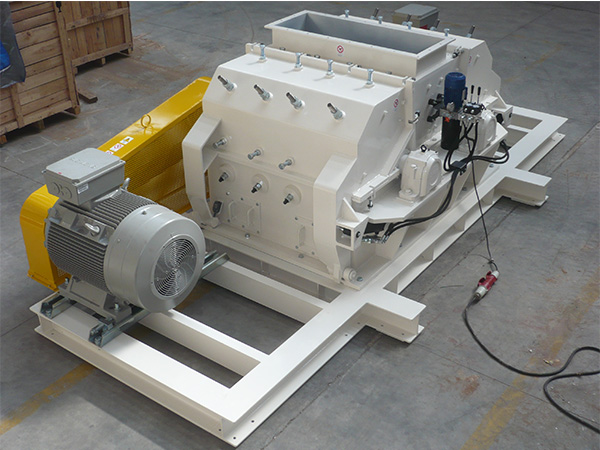

The twin rotor construction of our hammer mills ROTODUE 4M – 4MXP – 4GX – 4GZ offers the following interesting advantages:

- Double volume of grinding chamber and double surface of the discharge grate, for a given width of the mill. The capacity of the mill and the throughput of hot gaz for drying are, by consequence, increased consistently.

- The machine can work at high tip speed.

- The mill can be adapted to many different applications, even with relatively abrasive materials, with proper choice of feed opening position and rotor type.

- Ideal for production of products minus 0,5 ÷ 3 mm., depending on installation and working conditions.

- The product shape is well rounded or poliedric.

- Fine grinding of friable materials of medium hardness and abrasiveness.

- Contemporary drying and grinding blowing hot gas through the mill.

- Strong construction and easy maintenance.

| TYPE | ROTODUE 4M GX 500 | ROTODUE 4M GZ 750 | ROTODUE 4M GX 1000 | |

| Feed inlet | mm | 300 x 570 | 300 x 780 | 300 x 1120 |

| Maximum feed size: | ||||

| – with disc rotor/swinging hammers | mm | 40 | 40 | 40 |

| – with drum rotor/fixed hammers | mm | 100 | 100 | 100 |

| speed | rpm | 1000÷1750 | 1000÷1650 | 1000÷1650 |

| Requested power | kW | 2 x 45 ÷ 55 | 2 x 75 ÷ 90 | 2 x 90 ÷ 110 |

| Approx capacity | ton/h | 15÷25 | 25÷35 | 40÷60 |

| Weight | Kg | 5000 | 7000 | 10000 |

The data and characteristics of this table are informative and subject to change without prior notice.