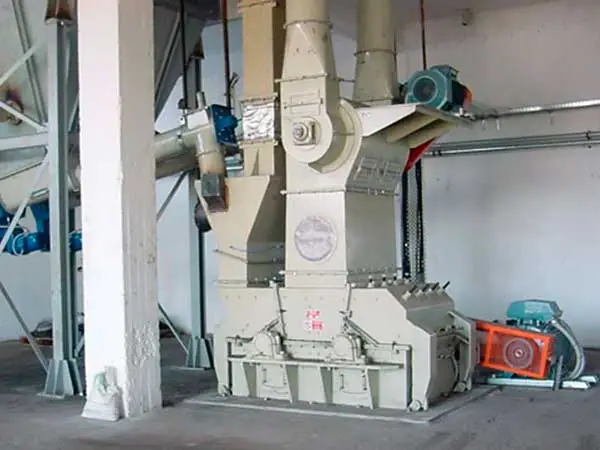

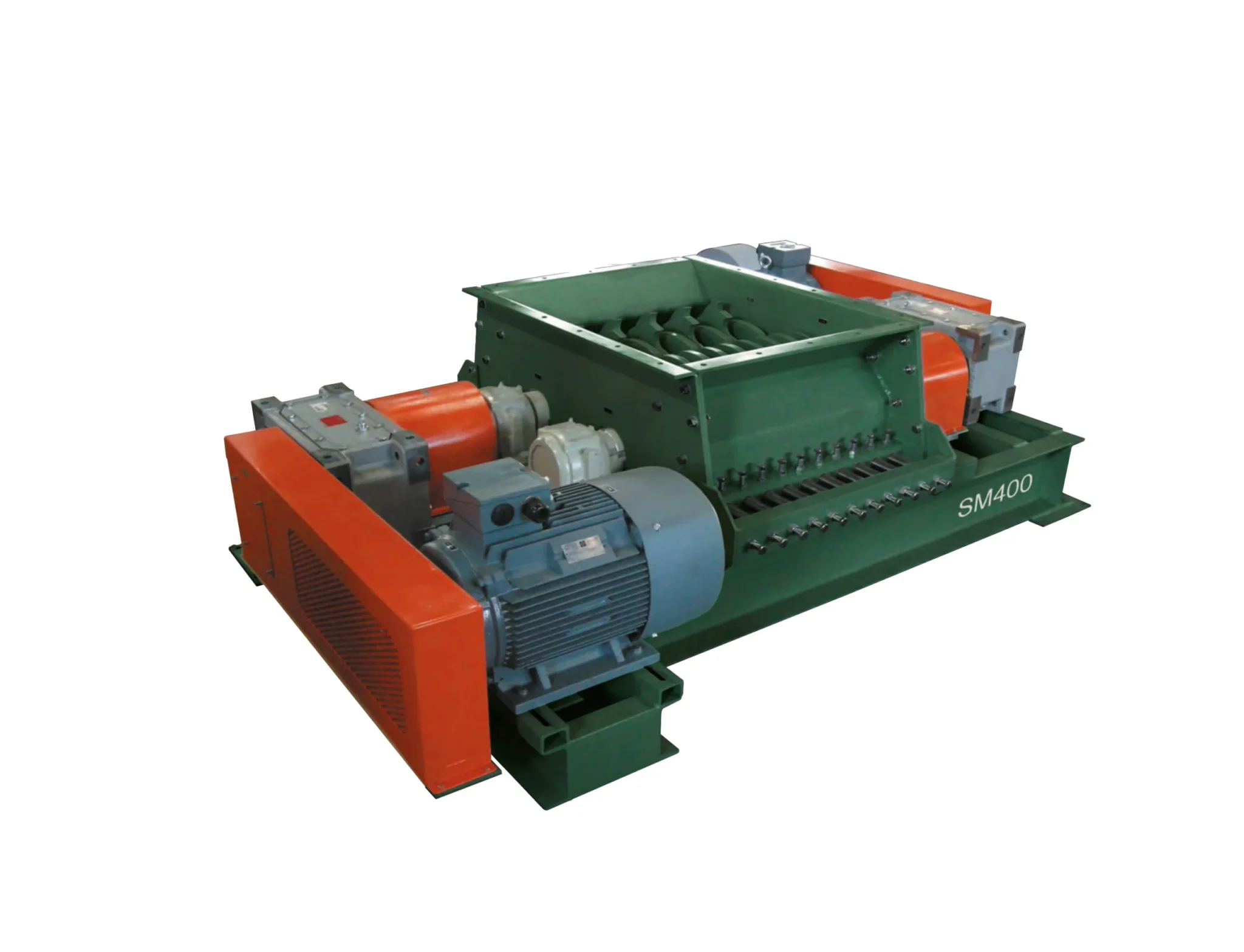

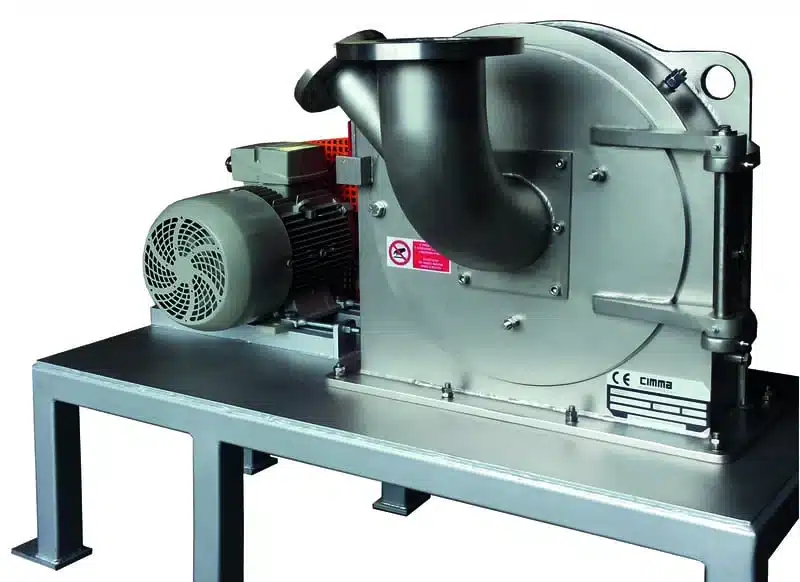

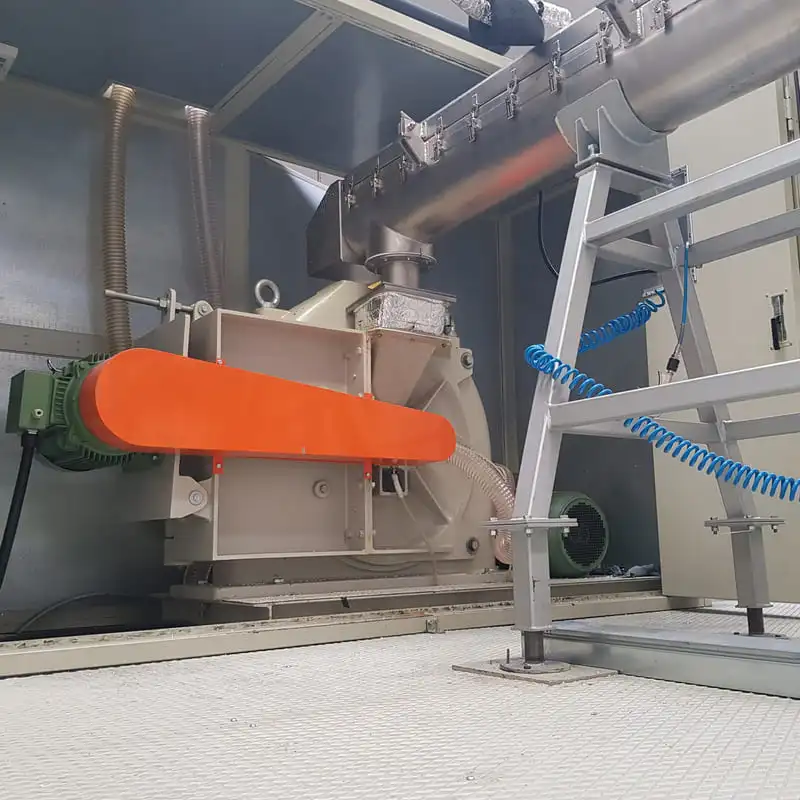

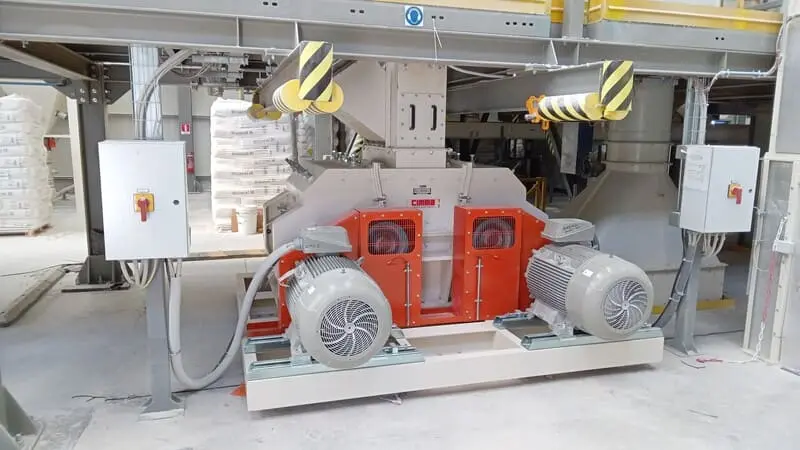

The PD-type pendular track and roller mill stands out for its operational efficiency, fineness adjustment (20-400 microns) and compatibility with chemical and mineral materials of medium hardness. Also available in a version with integrated drying, it is ideal for grinding friable materials, including wet materials, such as clay, kaolin, calcium carbonate, bentonite and dolomite.

Input power supply: 0 to 20 mm

Fineness range: 40 to 300 microns

Scope: 5 ÷ 20 t/hour Continue reading

Fineness range: 40 to 300 microns

Scope: 5 ÷ 20 t/hour Continue reading