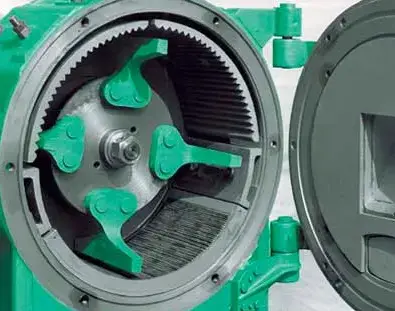

“ROTODUE 4M-GX” hammer and double rotor mill

Input power supply: less than 100 mm

Fineness range:0 ÷ 3 mm

Scope: up to 70 t/hour

Industrial grinding is an important process in that it serves to improve the characteristics of materials so that they become suitable for subsequent production steps. It also gives them the added value that is desired.

CIMMA is your specialized partner, offering state-of-the-art mills and grinding technologies for a wide range of industries.

CIMMA Morandotti S.P.A. is a leader in the design of customized industrial grinding equipment for key sectors such as ceramics, mining, chemical, food and biomass. Our grinding mills offer advanced solutions to meet any specific need for size reduction and material preparation:

“Rely on CIMMA to optimize your production process and gain lasting competitive advantages.”

Getting the desired particle size accurately is crucial to the efficiency of your production processes and the quality of your final products.

With our grinding equipment, you can improve your raw materials by reducing the particle size to achieve the right distribution. This improves reactivity, solubility and homogeneity. In addition, you can improve many other important properties, such as ensuring a uniform particle output. Optimal grinding results in a tangible competitive advantage in your target market.

CIMMA does more than just provide high-quality grinding mills. With our state-of-the-art testing facilities and a specialized technical team, we offer you comprehensive support in the development of advanced grinding processes, including risk analysis and solutions for explosion protection in potentially explosive atmospheres.

We actively collaborate with you to improve production efficiency: we study the best solution for your needs, whether through hammer blows with a hammer mill or the use of a ball mill or fixed hammer technologies, ensuring an effective and tailor-made industrial grinding plant.

Our expertise extends to cement production and cement grinding, with a focus on reducing the risk of dust explosions and controlling explosion pressure in air mixtures to minimize the risk of explosion. Thanks to our experience, we can deliver safe and efficient systems designed to meet stringent work protecting standards.